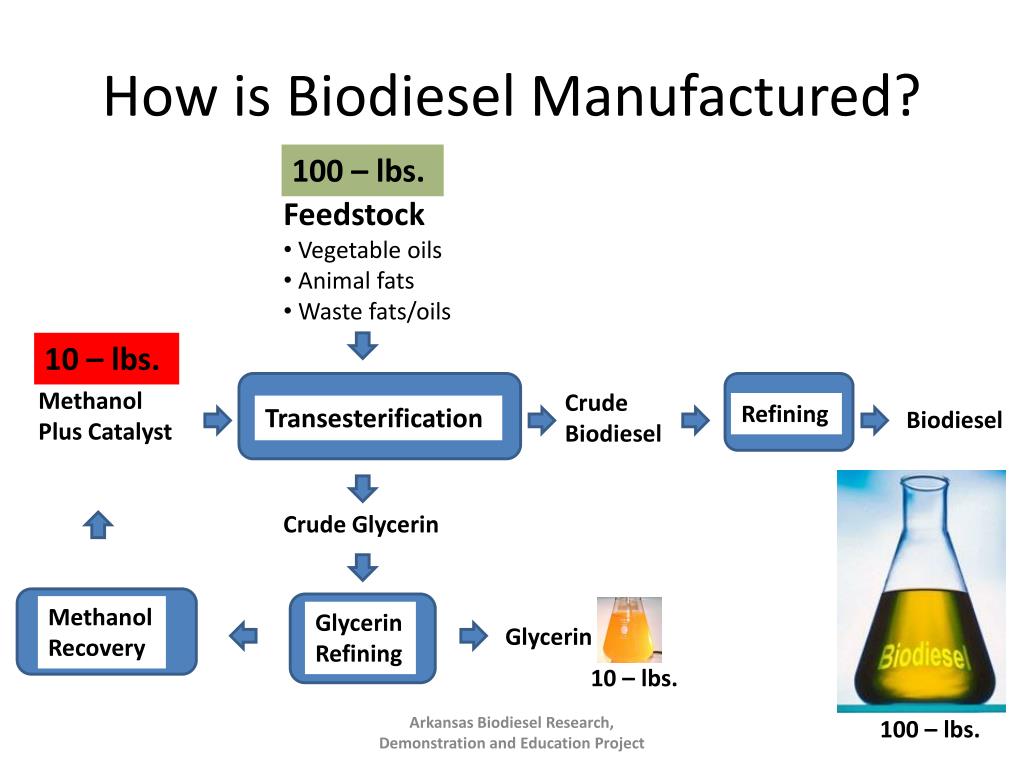

Biodiesel Production Process Flow Diagram

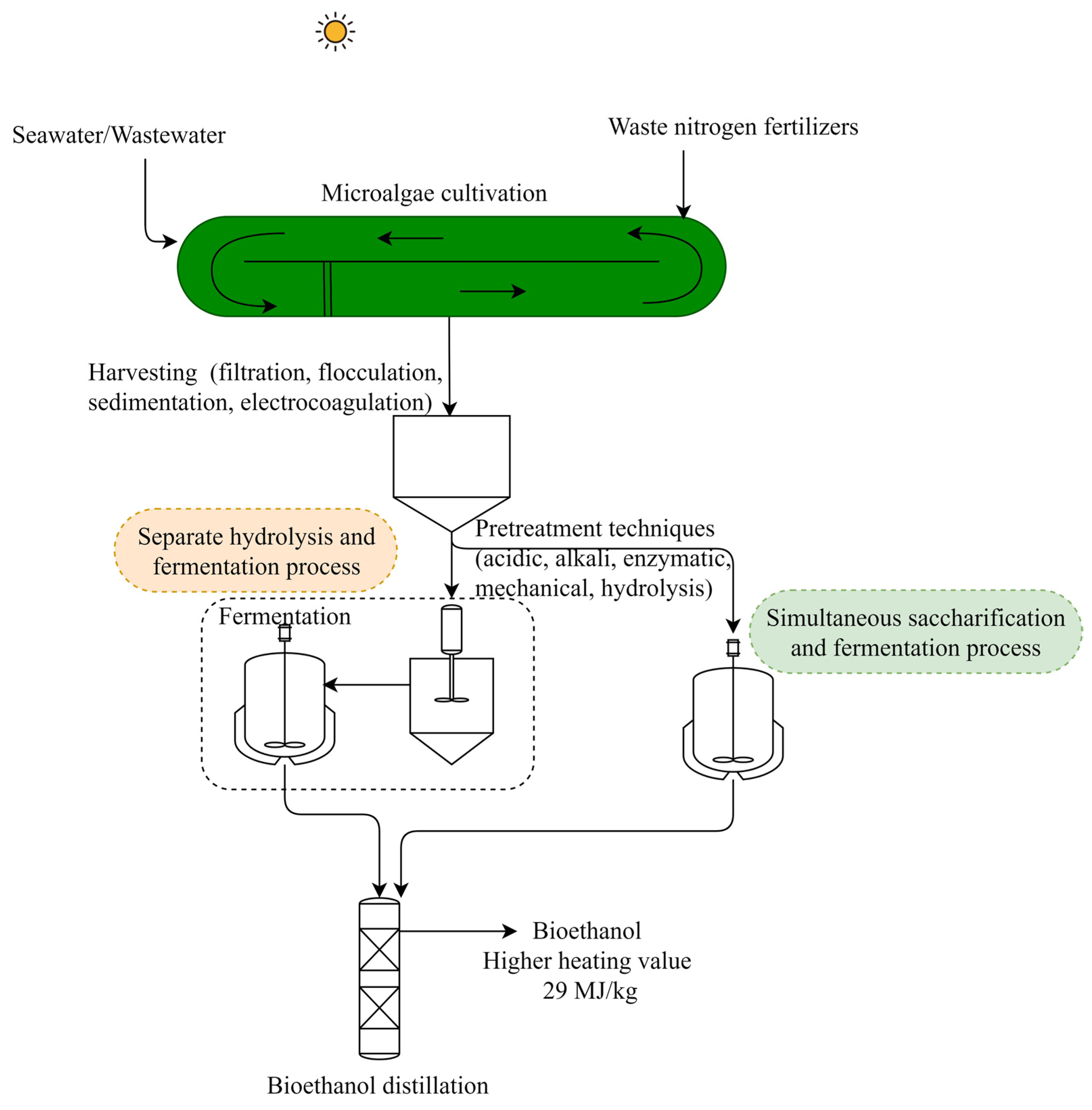

The factors affecting each stage of the microalgal biodiesel production process are detailed below (Chhandama et al., 2021). FIGURE 7.. In heterotrophic mode, microalgae utilizes external carbon sources to grow in a dark environment.. a microalgae cultivation technique was developed to treat wastewater in oil production. The data from.

Biodiesel fuel life cycle explanation with all usage stages outline diagram. Labeled educational

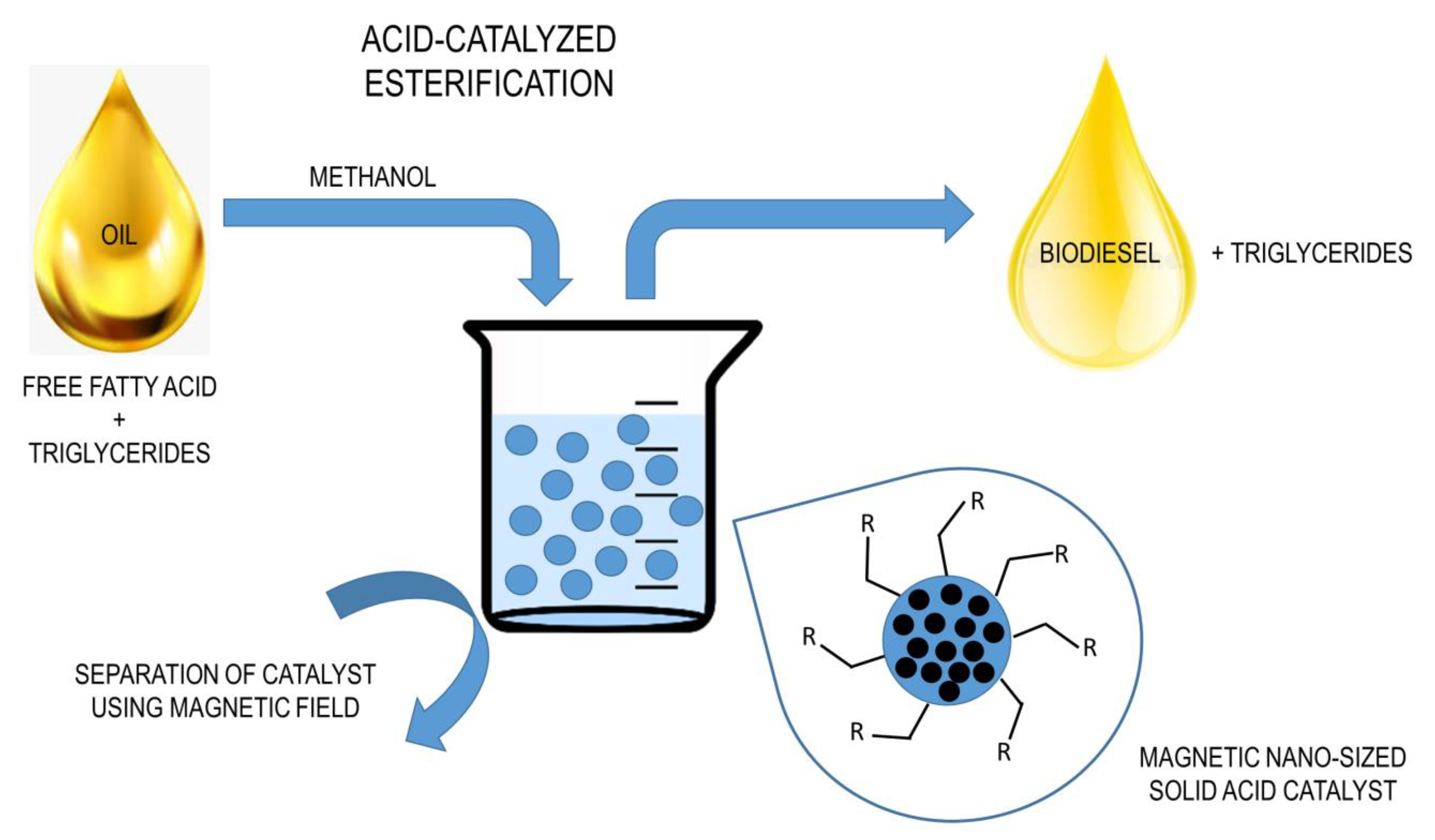

Biodiesel comparable to conventional diesel was obtained from heterotrophic microalgal oil by acidic transesterification. The best process combination was 100% catalyst quantity (based on oil weight) with 56:1 molar ratio of methanol to oil at temperature of 30 degrees C, which reduced product specific gravity from an initial value of 0.912 to a final value of 0.8637 in about 4h of reaction time.

Cyclic representation of biofuel production from algae. Download Scientific Diagram

For a non‐integrated plant, the production cost of the microalgae biodiesel was estimated at 2.51 and 2.27 $/liter for fed‐batch and continuous processes, respectively.

PPT Biodiesel PowerPoint Presentation, free download ID1621143

With an energy content of 5-8 kWh/kg (18,000-28,800 kJ/kg dry cell weight), feasibility of microalgal biodiesel production with respect to energy security, can be ascertained if the amount of energy required to produce and process the microalgal biodiesel is found to be lower than the energy contained per dry weight of the alga (Yuan et al., 2015).

Schematic representation of biodiesel production system from waste... Download Scientific Diagram

The microalgal BD production cost is also higher than that of fossil diesel [4,26]. According to Chung et al. [27], to cost-effectively produce BD from microalgae, the availability of mi-croalgal biomass, synthetic extraction procedure, and production of high-quality microalgal BD must be considered.

SciELO Brasil BIODIESEL SYNTHESIS FROM WASTE COOKING OIL USING A VARIETY OF WASTE MARBLE AS

Biodiesel comparable to conventional diesel was obtained from heterotrophic microalgal oil by acidic transesterification. The best process combination was 100% catalyst quantity (based on oil weight) with 56:1 molar ratio of methanol to oil at temperature of 30 degrees C, which reduced product specific gravity from an initial value of 0.912 to a final value of 0.8637 in about 4h of reaction time.

Microalgal Biotechnology Shannon ABC Applied Biotechnology Centre

Thus, heterotrophy can be used to reduce the cost of biodiesel oil production, but the effectiveness of the various organic carbons in supporting cell growth and oil accumulation depends on the strain and other culture conditions.. Miao XL, Wu Q (2006) Biodiesel production from heterotrophic microalgal oil. Bioresour Technol 97:841-846.

Process flowsheet of biodiesel production from vegetable oil. Download Scientific Diagram

An important challenge for the viability of commercial microalgal biodiesel production is the lower biomass and lipid productivity of large-scale outdoor microalgae cultivation . For instance, Lu et al. [ 132 ] observed that the biomass productivity of Chlorella sp. in an outdoor PBR was more than 50% lower compared to bench-scale indoor conditions, while the lipid productivity was three times.

Fermentation Free FullText Microalgal Feedstock for Biofuel Production Recent Advances

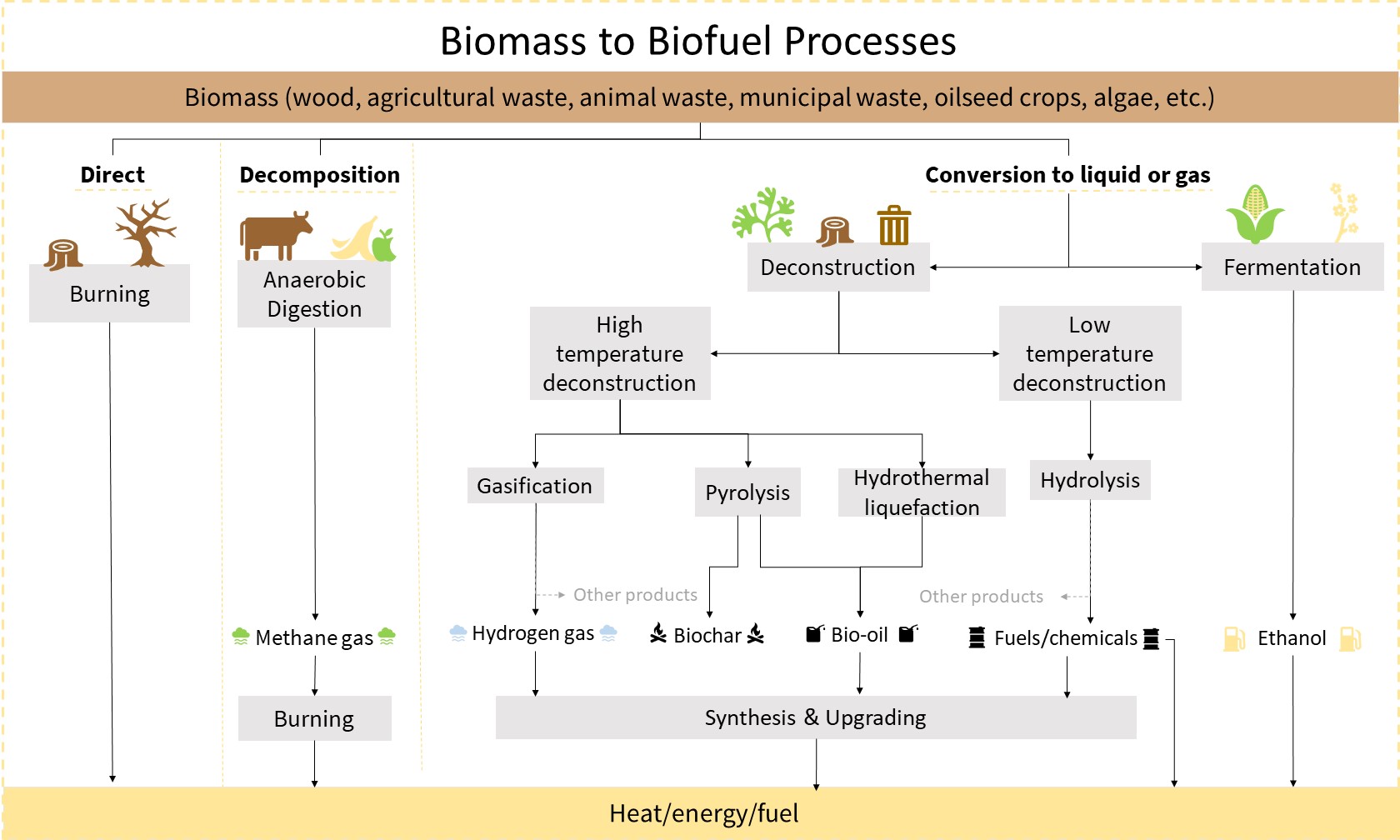

Biofuels, as a renewable, eco-friendly, and cost-effective energy source, can reduce the dependence on fossil fuels. The researchers considered different approaches for obtaining high biodiesel yields from microalgae biomass. This work aims to present an overview of the feasibility of microalgae use in biodiesel production. Therefore, biodiesel production from microalgae oil via the.

Biodiesel Production Reaction

The present review is focused on the use of heterogeneous catalysts for biodiesel production from microalgal oil as a reliable feedstock with a comparison to other available feedstocks. It also highlights optimal reaction conditions for maximum biodiesel yields, reusability of the solid catalysts, cost, and environmental impact..

(PDF) Biodiesel Production From Algae Principles And Processes

The present study introduced an integrated method for the production of biodiesel from microalgal oil. Heterotrophic growth of Chlorella protothecoides resulted in the accumulation of high lipid content (55%) in cells. Large amount of microalgal oil was efficiently extracted from these heterotrophic cells by using n-hexane.Biodiesel comparable to conventional diesel was obtained from.

Biofuel Production USDA Climate Hubs

Each 9.12 g (about 0.01 mol) of microalgal oil In the present study, an integrated method for biodiesel was used in all experiments. production from heterotrophic microalgal oil by acidic transesterification was developed. The characteristics 2.3. Acidic transesterification of microalgal oil of acidic transesterification of microalgal oil.

Waste cooking oil biodiesel production Download Scientific Diagram

Biodiesel comparable to conventional diesel was obtained from heterotrophic microalgal oil by acidic transesterification. The best process combination was 100% catalyst quantity (based on oil.

Microalgal biodiesel synthesis process flow different extraction and... Download Scientific

Biodiesel comparable to conventional diesel was obtained from heterotrophic microalgal oil by acidic transesterification. The best process combination was 100% catalyst quantity (based on oil weight) with 56:1 molar ratio of methanol to oil at temperature of 30 °C, which reduced product specific gravity from an initial value of 0.912 to a final value of 0.8637 in about 4 h of reaction time.

Figure 1 from Production of single cell oil for biodiesel from microalgae Chlorella

The factors affecting each stage of the microalgal biodiesel production process are detailed below (Chhandama et al., 2021). Open in a separate window.. In heterotrophic mode, microalgae utilizes external carbon sources to grow in a dark environment.. a microalgae cultivation technique was developed to treat wastewater in oil production.

(PDF) Biodiesel production from heterotrophic microalgal oil karen Bautista Academia.edu

Autotrophic versus heterotrophic culture conditions can have a substantial effect on cell density and lipid production during microalgal growth. Heterotrophic cultures of Chlorella protothecoide yielded up to four times the lipid yields (>55% dry weight basis) than autotrophic cultures of that microalga (Hildebrand et al., 2012).